Chemical Engineering

The Role of Process Flow Diagrams, Piping and Instrument Diagrams, Heat and Mass Balance Diagrams,

and Hydraulic Analysis in Chemical Engineering

and Hydraulic Analysis in Chemical Engineering

Download Brochure

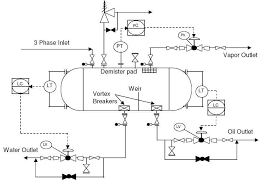

In the field of chemical engineering, the effective design and operation of industrial processes rely on various tools and diagrams. This content explores the essential concepts and applications of Process Flow Diagrams (PFDs), Piping and Instrument Diagrams (P&IDs), Heat and Mass Balance Diagrams, and Hydraulic Analysis, showcasing their significance in chemical engineering.

Process Flow Diagrams (PFDs)

Process Flow Diagrams are schematic representations of chemical processes that show the flow of materials, energy, and information. PFDs are crucial for understanding the overall process and its various unit operations.

Applications:

- Process Optimization: PFDs, P&IDs, and heat and mass balance diagrams are instrumental in optimizing chemical processes by identifying areas for improvement and efficiency enhancement

- Safety: P&IDs play a pivotal role in ensuring the safe operation of chemical processes by clearly depicting safety features, relief systems, and emergency shutdown procedures.

- Equipment Design: Heat and mass balance diagrams guide the design and operation of equipment like heat exchangers and reactors, enabling engineers to maximize efficiency and minimize environmental impact.

- Energy Efficiency: Hydraulic analysis helps engineers design energy-efficient piping systems, reducing operating costs and environmental impact.

- Project Management: Line Lists, Equipment Lists, and Piping Design Basis documents aid in project planning, execution, and monitoring by providing a clear roadmap for design and construction teams.

- Quality Assurance: Piping Material Specifications and Technical Specifications ensure that the materials and equipment used in the process meet the required quality standards, reducing the risk of failures and accidents.

- Space Optimization:Indicative Plot Plans and General Arrangements play a vital role in optimizing space within a facility, ensuring efficient layout design and compliance with safety regulations.

- Equipment Procurement: Technical specifications and datasheets assist in the procurement process by helping engineers select the most suitable equipment for the project's needs.